Waste Water Heat Recovery for Showers

Specify Recoup WWHRS

To specify Recoup WWHRS products select the product name from the links below and copy the product specification text, or download the text file link to insert the content into the specification details for your project.

Download a copy of our Energy Statement Overview & Specification Outline

Download a copy of our Energy Statement Overview & Specification Outline

Our Energy Satatement and Specification Outline should be used to specify WWHRS products. Providing a statement of WWHRS energy saving, full installation method comparison, and all details for specification of any Recoup WWHRS product.

Recoup Pipe HEX

Recoup WWHRS | Pipe HEX | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

VERTICAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Pipe HEX

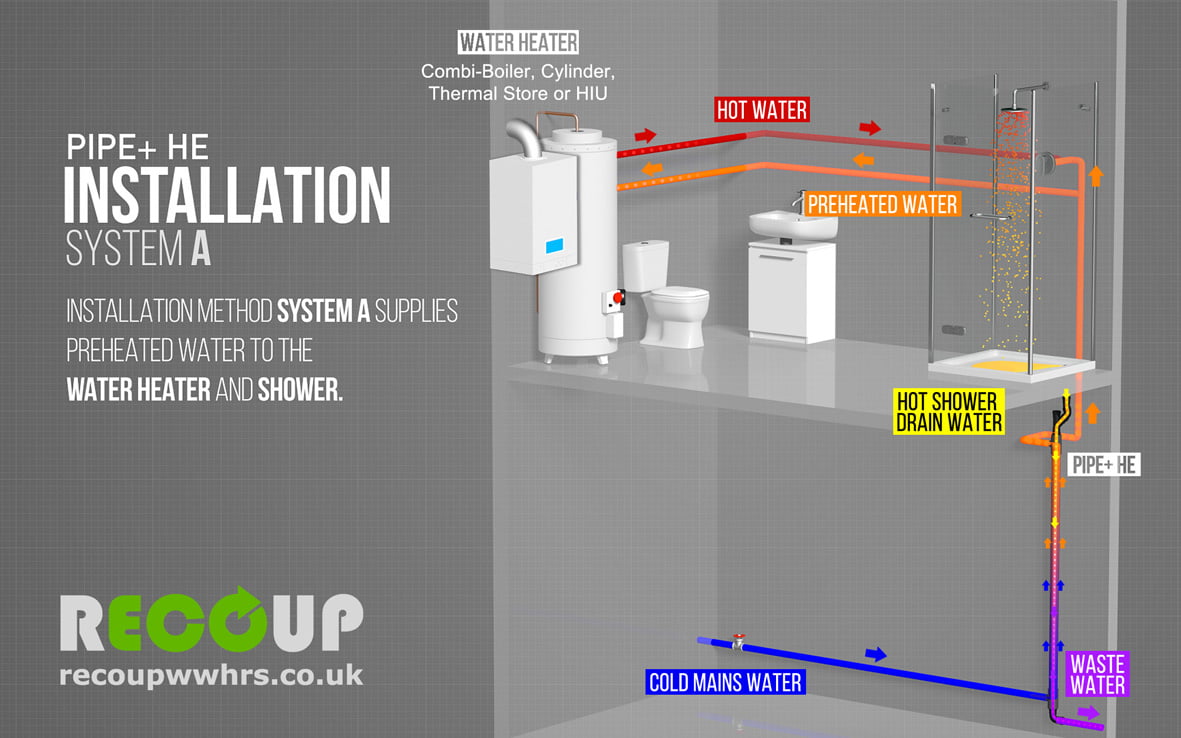

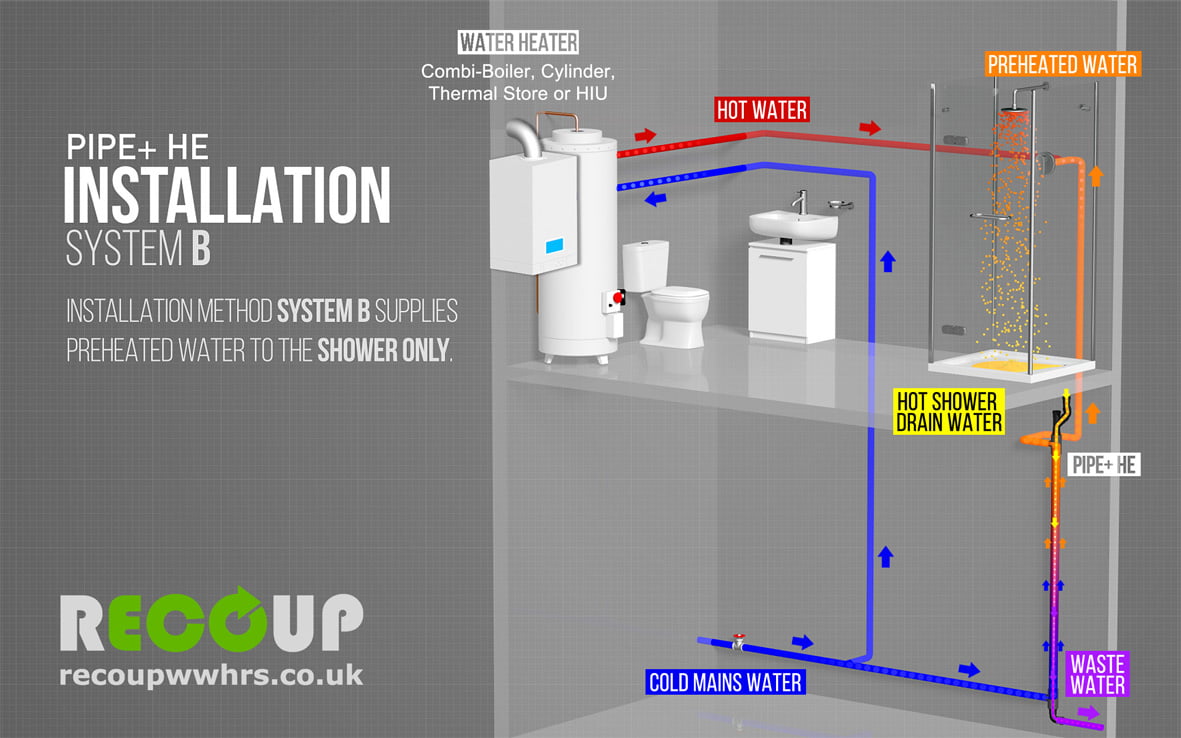

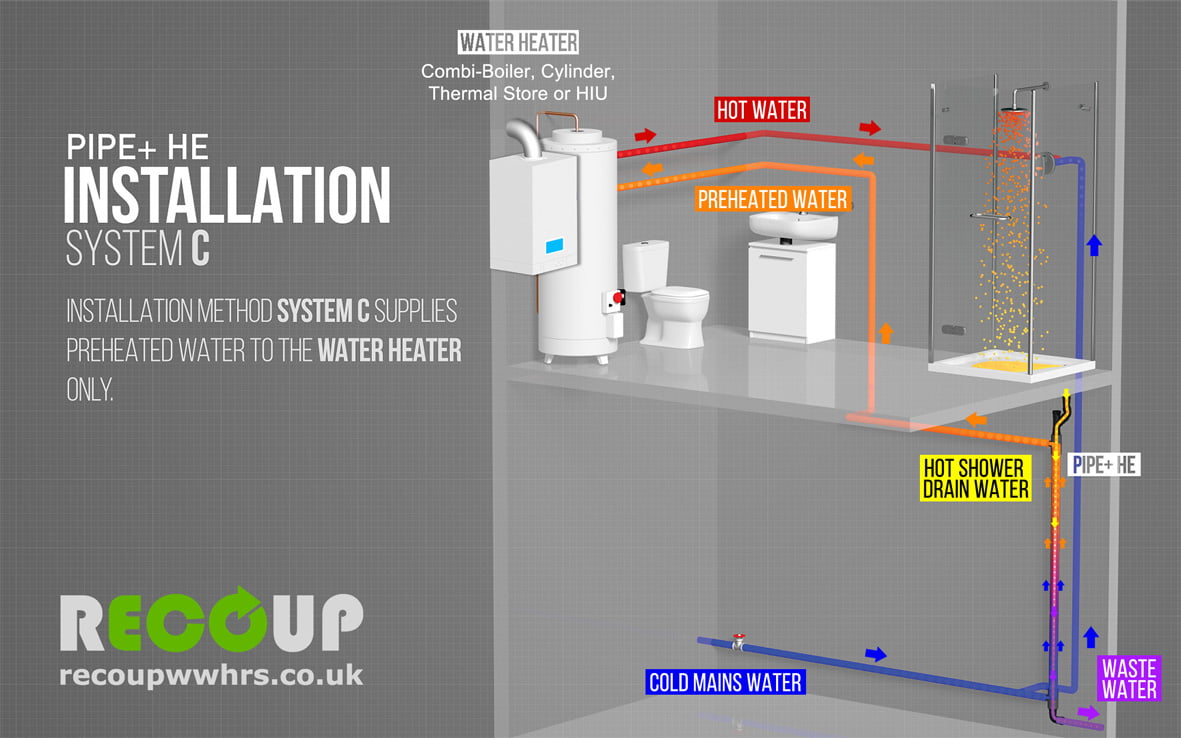

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 63.6%; System B= 49.9%; System C= 54.0% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.972

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: PVC outer casing, 100% recyclable material at end of life

- Length: 2100mm

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Pipe HEX specification text file

Recoup Pipe HEX Rd

Recoup WWHRS | Pipe HEX Rd | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

VERTICAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Pipe HEX Rd

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 57.3%; System B= 45.3%; System C= 49.6% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.973

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: PVC outer casing, 100% recyclable material at end of life

- Length: 1700mm

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Pipe HEX Rd specification text file

Recoup Pipe HEX Be

Recoup WWHRS | Pipe HEX Be | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

VERTICAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Manufacturer: Recoup WWHRS

- Product reference: Pipe HEX Be

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A ≤ 63.6%; System B ≤ 49.9%; System C ≤ 54.0% (delete as appropriate)

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: PVC outer casing, 100% recyclable material at end of life

- Length: Between 1065mm and 2100mm

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Pipe HEX Be specification text file

Recoup Pipe HEX Active

Recoup WWHRS | Pipe HEX Active | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

ACTIVE VERTICAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Pipe HEX Active

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 63.6%; System B= 49.9%; System C= 54.0% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.972

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: PVC outer casing, 100% recyclable material at end of life

- Length: 2100mm

- Uses Pump: Yes

- Notional Pump Power: 75W at 9.0 l/min, 93W at 11.0 l/min (delete as appropriate)

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Pipe HEX Active specification text file

Recoup Pipe HEX Rd Active

Recoup WWHRS | Pipe HEX Rd Active | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

ACTIVE VERTICAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Pipe HEX Rd Active

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 57.3%; System B= 45.3%; System C= 49.6% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.973

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: PVC outer casing, 100% recyclable material at end of life

- Length: 1700mm

- Uses Pump: Yes

- Notional Pump Power: 75W at 9.0 l/min, 93W at 11.0 l/min (delete as appropriate)

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Pipe HEX Rd Active specification text file

Recoup Easyfit+

Recoup WWHRS | Easyfit+ | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

HORIZONTAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Easyfit+

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 43.6%; System B= 35.2%; System C= 39.2% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.972

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: 100% Recycled ABS outer casing

- Length: 1100mm

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Easyfit+ Specification text file

Recoup Drain+ Compact

Recoup WWHRS | Drain+ Compact | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

HORIZONTAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Drain+ Compact

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 37.0%; System B= 30.4%; System C= 33.8% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.978

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: Stainless steel

- Size: 860 x 188 x 114mm

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Drain+ Compact Specification text file

Recoup Drain+ Duo

Recoup WWHRS | Drain+ Duo | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

HORIZONTAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Drain+ Duo

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 40.4%; System B= 32.9%; System C= 36.6% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.974

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: Stainless steel

- Size: 866 x 240 x 165mm

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Drain+ Duo Specification text file

Recoup Drain+ Duo HE

Recoup WWHRS | Drain+ Duo HE | Installed as System A; System B; System C (delete as appropriate) | to (Add shower(s) install location)

HORIZONTAL WASTE WATER HEAT RECOVERY FOR SHOWERS (WWHRS)

- Standard: WRAS Approved.

- Performance: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 (SAP 2012)

- Manufacturer: Recoup WWHRS

- Product reference: Drain+ Duo HE

- Installation method / Model Qualifier: System A; System B; System C (delete as per system(s) specified)

- Minimum Heat Recovery Efficiency (SAP 2012): System A= 56.7%; System B= 44.9%; System C= 49.2% (delete as appropriate)

- Minimum Utilisation Factor (SAP 2012, System A): 0.966

- Heat Exchanger material: Copper (Double-walled, EN1717 compliant), 100% recyclable material at end of life

- Casing / Finish: Stainless steel

- Size: 866 x 240 x 205mm

- Accessories: 1no Double Check Valve; 2no Isolator valves.

- Installation: According to manufactures instruction; to comply with Legionella Control Risk Assessment Guidance; and BS EN 1717:2000

Download Recoup Drain+ Duo HE Specification text file

Recoup Legacy Products

Recoup Retrofit+ discontinued 2017** replace with Recoup Easyfit+; Recoup Pipe HEX Active; Recoup Pipe HEX Rd Active

Recoup Drain+ (900) discontinued 2020** replace with either Recoup Drain+ Compact; Recoup Drain+ Duo; Recoup Drain+ Duo HE

Recoup Tray+ DSS-S2 discontinued 2021** replace with either Recoup Drain+ Compact; Recoup Drain+ Duo; Recoup Drain+ Duo HE; Recoup Pipe HEX Active; Recoup Pipe HEX Rd Active

Recoup Pipe+ HE discontinued 2021** replace with Recoup Pipe HEX

**dimensions and SAP calculations should be checked and confirmed before changing specification.

The Recoup Knowledge Base is our fully searchable library of information available 24 hours a day. Quickly find answers to common questions or deep-dive full in-depth technical articles, product information and design walk-thrus, as well as, key articles, industry news and a growing list of case studies.

Visit Recoup Knowledge Base.